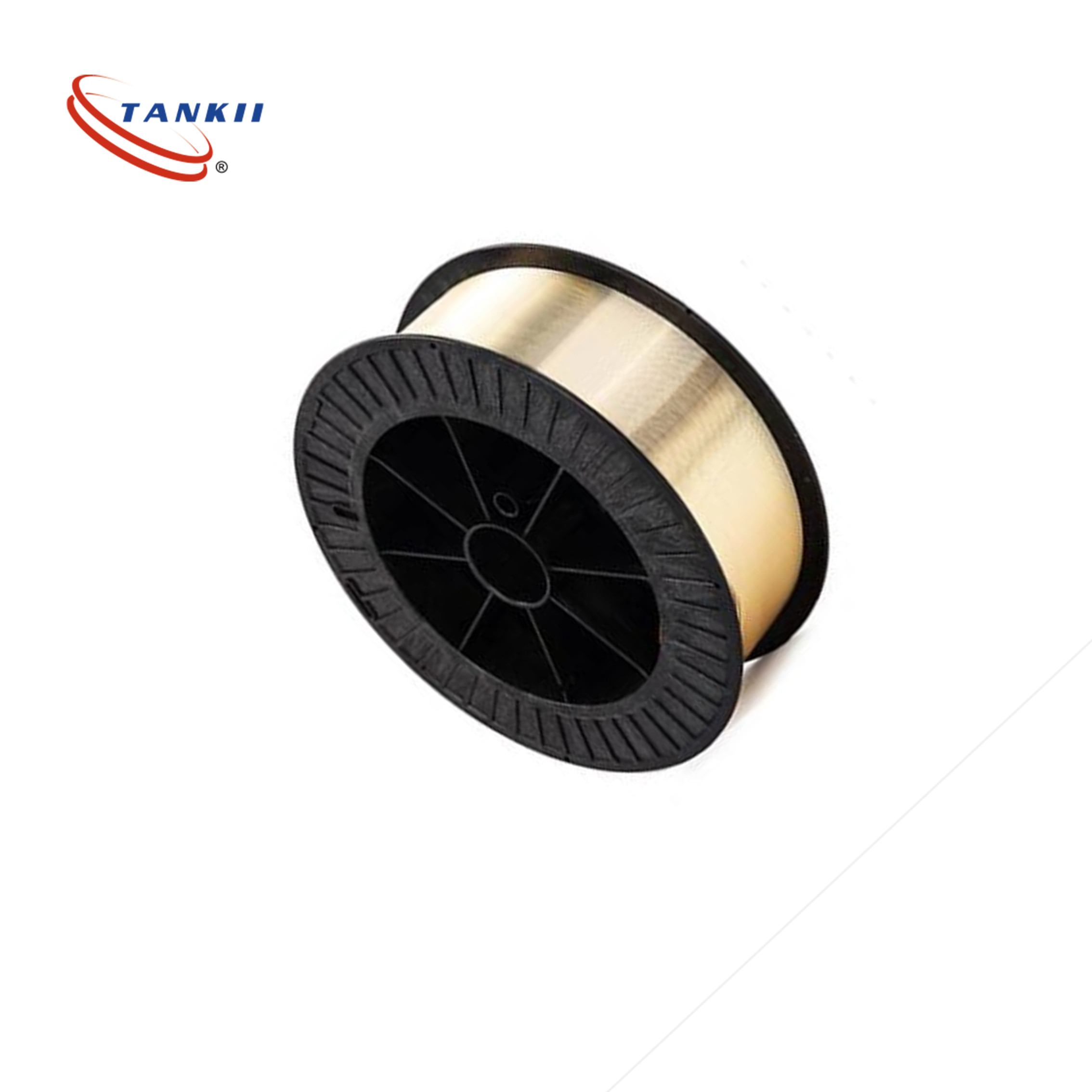

Enamelled CuNi45/CuNi44/CuNi40 copper nickel Alloy Wire

Enamelled CuNi45/CuNi44/CuNi40 Alloy Wire

Product Description

These enameled resistance wires have been broadly used for standard resistors, automobile

parts, winding resistors, etc. using the insulation processing best suited for these applications, taking full advantage of the distinctive features of enamel coating.

Furthermore, we will carry out enamel coating insulation of precious metal wire such as silver and platinum wire upon order. Please make use of this production-on-order.

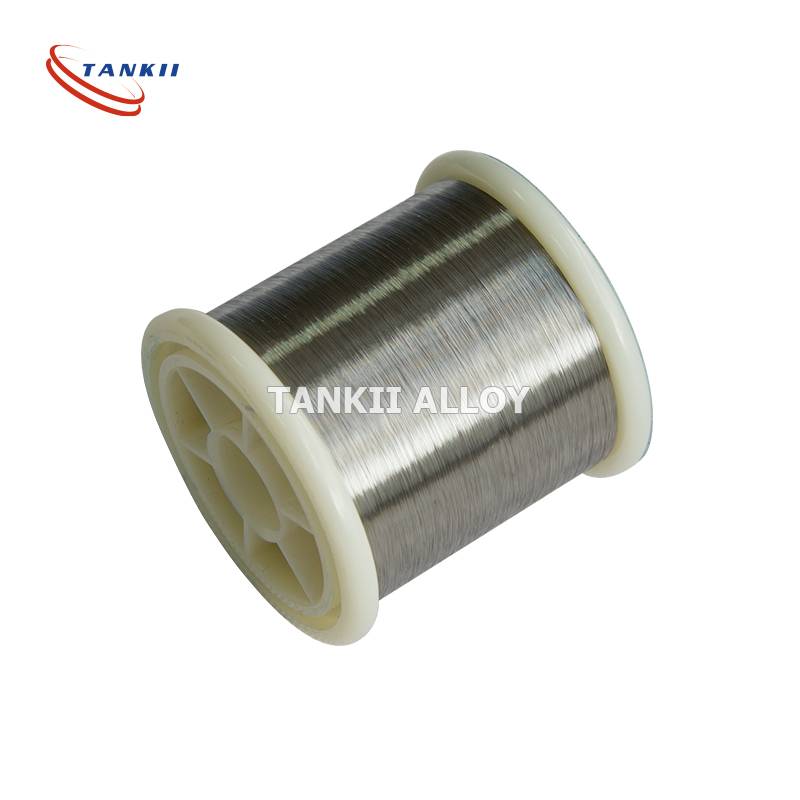

Type of bare Alloy wire

The alloy we can do enamelled are Copper-nickel alloy wire,Constantan wire,Manganin wire. Kama Wire,NiCr Alloy wire,FeCrAl Alloy wire etc alloy wire

Type of insulation

| Insulation-enamelled Name | Thermal LevelºC (working time 2000h) |

Code Name | GB Code | ANSI. TYPE |

| Polyurethane enamelled wire | 130 | UEW | QA | MW75C |

| Polyester enamelled wire | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled wire | 180 | EIW | QZY | MW30C |

| Polyester-imide and polyamide-imide double coated enameled wire | 200 | EIWH (DFWF) |

QZY/XY | MW35C |

| Polyamide-imide enamelled wire | 220 | AIW | QXY | MW81C |

Chemical Content, %

| Ni | Mn | Fe | Si | Cu | Other | ROHS Directive | |||

| Cd | Pb | Hg | Cr | ||||||

| 44 | 1% | 0.5 | - | Bal | - | ND | ND | ND | ND |

Mechanical Properties

| Max Continuous Service Temp | 400ºC |

| Resisivity at 20ºC | 0.49±5%ohm mm2/m |

| Density | 8.9 g/cm3 |

| Thermal Conductivity | -6(Max) |

| Melting Point | 1280ºC |

| Tensile Strength,N/mm2 Annealed,Soft | 340~535 Mpa |

| Tensile Strength,N/mm3 Cold Rolled | 680~1070 Mpa |

| Elongation(anneal) | 25%(Min) |

| Elongation(cold rolled) | ≥Min)2%(Min) |

| EMF vs Cu, μV/ºC (0~100ºC) | -43 |

| Micrographic Structure | austenite |

| Magnetic Property | Non |

Application of Constantan

Constantan is a copper-nickel alloy that contains specific minor amounts of additional

elements to achieve precise values for the temperature coefficient of resistivity. Careful

control of melting and conversion practices results in a very low level of pinholes at

ultra-thin thicknesses. The alloy is used extensively for foil resistors and strain gauges.