Welcome to our websites!

Tankii Heater For Electric Tubular Bayonet Heater Elements Heat Element Iron Industrial Oven Heating Elements

Production Description:

Bayonet heating elements are a reliable and efficient solution for electric heating applications. Bayonets are rugged, deliver a lot of power and are extremely versatile when used with radiant tubes.

These elements are custom designed for the voltage and input (KW) required to satisfy the application. There are a wide variety of configurations available in either large or small profiles. Mounting can be vertical or horizontal, with heat distribution selectively located according to the required process. Bayonet elements are designed with ribbon alloy and watt densities for furnace temperatures up to 1800°F (980°C).

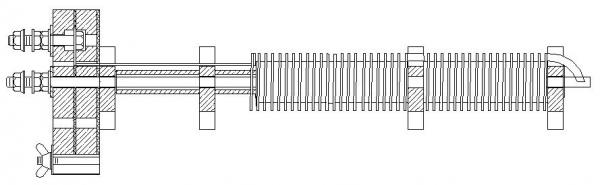

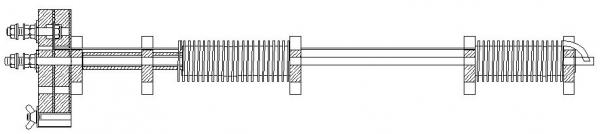

Horizontal Elements showing various locations for ceramic spacers

| ELEMENT O.D. (in.) (NiCr ALLOY) |

Max Kilowatts/Linear Foot | ELEMENT O.D. (in.) (FeCrAl ALLOY) |

||||

| UP TO 1000°F | 1000°F To 1350°F | 1350°F To 1700°F | 1700°F TO 2050°F | 2050°F TO 2250°F | ||

| 2 3/4 | 2.38 | 2.20 | 1.88 | 1.56 | ||

| 2.28 | 2.10 | 1.87 | 2 5/8 | |||

| 3 3/8 | 3.80 | 3.47 | 2.96 | 2.44 | ||

| 3.83 | 3.48 | 3.12 | 3 1/8 | |||

| 3 3/4 | 4.57 | 4.14 | 3.48 | 2.94 | ||

| 3.83 | 3.48 | 3.12 | 4 5/16 | |||

| 4 3/4 | 6.46 | 5.83 | 4.99 | 4.14 | ||

| 3.83 | 5.40 | 4.90 | 4 7/8 | |||

| 5 3/4 | 7.26 | 6.59 | 5.68 | 4.68 | ||

| 6.43 | 5.84 | 5.28 | 6 | |||

| 6 1/8 | 8.12 | 7.36 | 6.32 | 5.27 | ||

| 7.28 | 6.60 | 6.00 | 6 3/4 | |||

| 7 3/4 | 9.76 | 8.86 | 7.62 | 6.36 | ||

Write your message here and send it to us