Welcome to our websites!

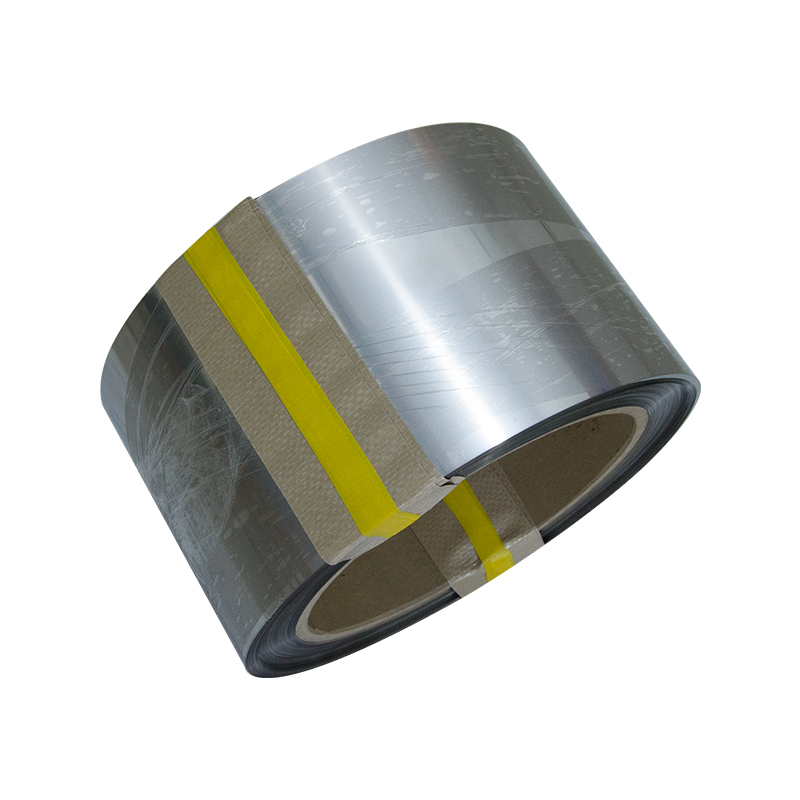

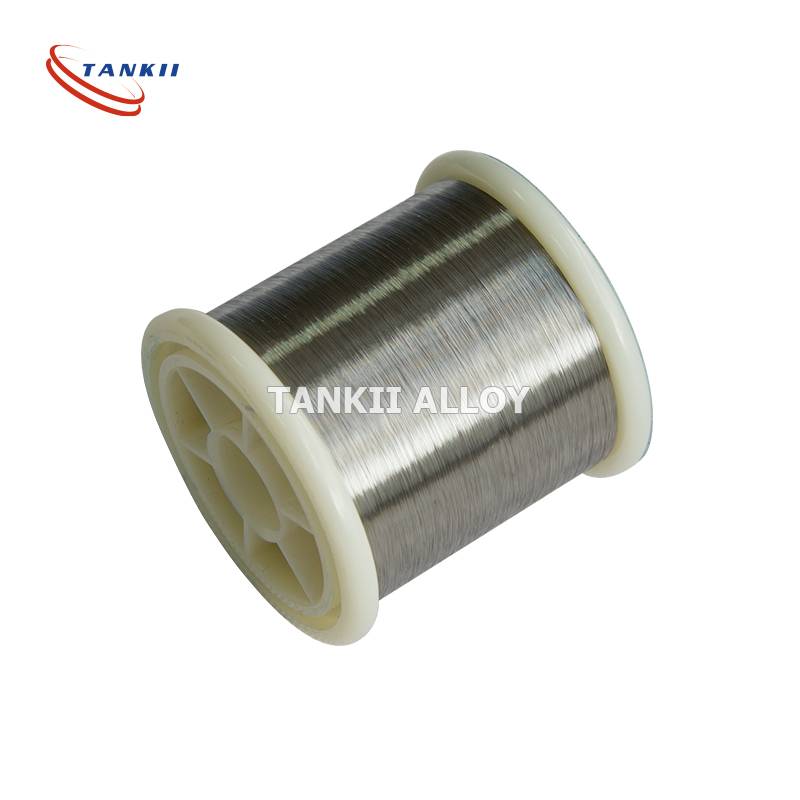

Factory Wholesale Price Copper Nickel Wire to Electrical Heating Resistance Wire

- Low electric resistance

- Good heat resistance

- Corrosion resistance

- Easy to process and lead welded

Applications:

- Low-voltage circuit breakers

- Thermal overload relays

- Electrical heating cables

- Electrical heating mats

- Snow melting cables and mats

- Ceiling radiant heating mats

- Floor heating mats & cables

- Freeze protection cables

- Electrical heat tracers

- PTFE heating cables

- Hose heaters

- Other low-voltage electrical products

Choose our Copper Nickel Alloy Wire for its exceptional performance and reliability. Contact us at Shanghai Tankii Alloy Material Co., Ltd. for more information.

| Characteristic | Resistivity ( 200C μΩ.m) | Max.working Temperature ( 0C) | Tensile Strength (Mpa) | Melting point (0C) | Density ( g/cm3) | TCR x10-6/ 0C (20~600 0C) | EMF vs Cu (μV/ 0C) (0~100 0C) |

| Alloy Nomenclature | |||||||

| NC005(CuNi2) | 0.05 | 200 | ≥220 | 1090 | 8.9 | <120 | -12 |

| Ni | Mn | Fe | Si | Cu | Other | ROHS Directive | |||

| Cd | Pb | Hg | Cr | ||||||

| 2 | - | - | - | Bal | - | ND | ND | ND | ND |

| Max Continuous Service Temp | 200ºC |

| Resisivity at 20ºC | 0.05±10%ohm mm2/m |

| Density | 8.9 g/cm3 |

| Thermal Conductivity | <120 |

| Melting Point | 1090ºC |

| Tensile Strength,N/mm2 Annealed,Soft | 140~310 Mpa |

| Tensile Strength,N/mm2 Cold Rolled | 280~620 Mpa |

| Elongation(anneal) | 25%(min) |

| Elongation(cold rolled) | 2%(min) |

| EMF vs Cu, μV/ºC (0~100ºC) | -12 |

| Micrographic Structure | austenite |

| Magnetic Property | Non |

| Main property | Cuni1 | CuNI2 | CuNI6 | CuNI10 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | |

| Main chemical composition | Ni | 1 | 2 | 6 | 10 | 19 | 23 | 30 | 34 | 44 |

| MN | / | / | / | / | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| CU | rest | rest | rest | rest | rest | rest | rest | rest | rest | |

| Max working Temperature °c | / | 200 | 220 | 250 | 300 | 300 | 350 | 350 | 400 | |

| Density g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Resistivity at 20 °c | 0.03 ± 10% | 0.05 ±10% | 0.1 ±10% | 0.15 ±10% | 0.25 ±5% | 0.3 ±5% | 0.35 ±5% | 0.40 ±5% | 0.49 ±5% | |

| Temperature coefficient of Resistance | <100 | <120 | <60 | <50 | <25 | <16 | <10 | -0 | <-6 | |

| Tensile strength Mpa | >210 | >220 | >250 | >290 | >340 | >350 | >400 | >400 | >420 | |

| Elongation | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | |

| Melting point °c | 1085 | 1090 | 1095 | 1100 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Coefficient of conductivity | 145 | 130 | 92 | 59 | 38 | 33 | 27 | 25 | 23 | |

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Top